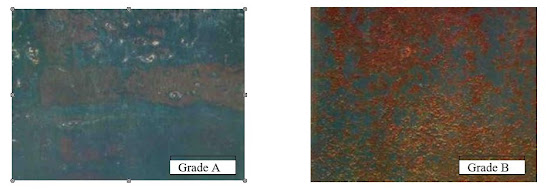

ISO 8501-1 Pictorial Standards of Cleanliness

ISO 8501-1 Pictorial Standards of Cleanliness

ISO 8501-1 is

a pictorial standard relating to surface cleanliness, amongst other methods,

though abrasive blasting. The original condition of steel surfaces prior to blasting are depicted in various

stages of corrosion as follows:

Grade A Steel

surface

largely covered

with adhering mill scale but little, if any rust

Grade B Steel surface which

has begun to rust and from which the mill scale has begun to flake

Grade C Steel surface on which the mill scale has ruted away or

from which it can be scraped, but with slight

pitting visible under normal vision.

Grade D Steel surface on which the mill scale has rusted away and on which general pitting is visible under normal vision

Standard notation usually, but not always,

includes the original

condition of steel

before blasting i.e. “B Sa3”.

Pictorial standards of

cleanliness (Sa1, Sa2, Sa2.5 and Sa3) are depicted overleaf.

Blast-cleaning to Sa Standards

Blast cleaning to ISO 8501-1 Sa standards is a commonly

used specification with pictorial and written guidelines as follows:

· Sa 1 Light blast -cleaning When viewed without magnification, the surface shall be free from visible oil, grease and dirt. And from poorly adhering mill scale, rust, paint coatings and foreign matter.

· Sa 2 Thorough blast-cleaning When viewed without magnification, the surface shall be free from visible oil, grease and dirt and from most of the mill scale, rust, paint coatings and foreign matter. Any residual contamination shall be firmly adhering.

· Sa 2½ Very thorough blast-cleaning When viewed without magnification, the surface shall be free from visible oil, grease and dirt and from mill scale, rust, paint coatings and foreign matter. Any remaining traces of contamination shall show only as slight stains in the form of spots or stripes.

· Sa 3 Blast-cleaning to visually clean steel When viewed without magnification, the surface shall be free from visible oil, grease and dirt and from mill scale, rust, paint coatings and foreign matter. It shall have a uniform metallic color.

Reference: www.satactics.com

No comments:

Post a Comment